Abstract

Cannabinoid extraction during Cannabis processing produces a wax by-product which is currently underutilised, partially because the composition is poorly understood. This study applied both gas and liquid chromatography methods to characterise the major compounds present in the waxy by-product from commercial Cannabis processing. Two industrial wax by-products (wax A and wax B) were used as the feedstock for the characterisation, differing in both strain of Cannabis used and downstream processing conditions. The main classes quantified in the Cannabis waxes were cannabinoids, n-alkanes, fatty alcohols, fatty acids, sterols, and various terpenoids. The cannabinoid fraction was the most abundant fraction in both waxes, reporting a total fraction of 509.3 mg/g for wax A and 392.6 mg/g for wax B, on a solvent-free basis. For wax A the largest remaining wax compound class was the fatty acids, which reported a concentration of 172.2 mg/g, with linoleic acid being the most abundant at a concentration of 68.47 mg/g. The most abundant wax compound class in wax B was the n-alkanes at a concentration of 54.55 mg/g and the dominant species in that fraction was nonacosane (C29) with a concentration of 24.47 mg/g. It can be concluded that due to the high concentration of cannabinoids remaining in the wax even after processing, and their relative commercial value, recovery of the cannabinoids from the wax could form a potential valorisation application for the underutilised Cannabis wax by-product.

Similar content being viewed by others

1 Introduction

With the increase in research done on Cannabis and its unique compounds, various extraction methods from either hemp fibres or Cannabis flowers are commercially used to produce valuable extracts [1]. The global market for Cannabis-derived products, i.e. cannabinoid isolates and extracts, was estimated to be USD 7.1 billion in 2020 with a projected compound annual growth rate (CAGR) of ~ 35% between 2021 and 2027. The market size of these products is projected to exceed USD 108.8 billion by 2027 [2], which necessitates an increase in production or process efficiency to meet the demands of the larger market.

Commercial cannabinoid extraction generally follows the route of primary solid–liquid extraction from plant material with ethanol, followed by a winterisation step to precipitate co-extracted plant waxes [3, 4]. Another effective extraction technique used is supercritical-CO2 (SC-CO2) extraction, which has been demonstrated to effectively extract the cannabinoids from the flowers at high purities [3, 5]. Ethanol can be added as a co-solvent during SC-CO2, which has been reported to extract cannabinoid acids at higher efficiencies [6]. However, the use of SC-CO2 also results in the co-extraction of waxes, and therefore, the winterisation stage for wax removal is also required when using this procedure. On an industrial scale, ethanol extraction is generally implemented [5].

The precipitated waxes are removed from the primary stream through filtration as the presence of lipophilic compounds in the extracts negatively affects the performance of the various downstream distillation stages and the product quality. The amount of wax generated is significant, at 5–10% (w/w) from biomass input is generated [7], and so the utilisation or valorisation of this Cannabis wax may hold significant potential in unlocking additional value from Cannabis processing. However, there remains significant uncertainty in the exact composition of the Cannabis by-product wax [7], which is an obstacle for potential further valorisation of this by-product. The wax differs from, for instance, hemp wax or hemp seed oil, as it is a co-extracted by-product and not a targeted extraction such as described in Noppawan et al. [8] or Montserrat-de la Paz et al. [9], who reported on the composition of Soxhlet extracted waxes from hemp and hemp seed oil, respectively. Due to the different extraction conditions and feed material used, the compositions of these products are significantly different.

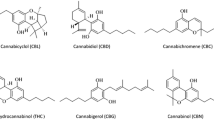

Identification and quantification of the major compounds present in these wax by-products would allow for the identification of individual compounds or groups of compounds to target for further recovery. Plant waxes are commonly composed of aliphatic compounds such as long-chain alkanes, fatty alcohols, fatty acids, and wax esters [10,11,12]. Cyclic compounds such as terpenoids and sterols are also present in most plant waxes, including those derived from Cannabis [7, 12, 13]. One might also expect a fraction of this wax to contain cannabinoids, since this wax is a by-product from cannabinoid extraction.

One study, conducted by Leyva-Gutierrez et al. [5], characterised Cannabis by-products, but the focus was aimed more towards the later by-products emerging from the distillation stages, i.e. resins and tars removed from the distillation column, as well as impurities in the final cannabidiol (CBD) isolate. The composition of these further downstream products will most certainly be significantly different from the winterisation wax, a stream which is also significantly larger in volume than those other waste streams. It was further reported that the generation of waste products from commercial Cannabis processing can be up to 58% (w/w relative to total crude extract) from all different processing stages, which due to lack of characterisation remain underutilised [7].

Waste residues and underutilised by-products, such as those generated by Cannabis processing, can effectively be converted through a biorefinery approach into value-adding products and materials, which through integration of process streams and stages can allow for the valorisation of multiple waste streams [14]. This concept is however dependent on knowledge of the composition of the feedstock, necessitating detailed characterisation of the streams before attempted valorisation [15]. A further complication is that the composition of these streams is likely variable, depending on processing route, and the source biomass (in this case a major differentiator might be whether the source Cannabis is from a high THC- or CBD-producing strain), and so a wide number of compositional studies examining various feedstocks will be useful for the bioprocess engineer designing such a biorefinery.

Analysis of plant waxes can be challenging in general due to the relatively high molecular weight of the lipophilic compounds found in the wax, and several problems that could arise during analysis are related to volatility, transport through the analytical columns, and elution from the columns [16]. In cases where compounds have difficulty eluting chemical derivatisation needs to be implemented to produce sufficiently volatile compounds [17]. Different methodologies for gas chromatography (GC) and liquid chromatography (LC) have already been established for the analysis of plant waxes [13, 18,19,20,21,22]; however, in order to create a clearer picture of plant wax compositions some of these methods can be combined or adapted for the analysed substrate.

This study aimed to fill to the gap in knowledge regarding the compositional characterisation of Cannabis processing wax by-products by the implementation of a targeted quantitative analysis to characterise the major compounds present in the wax by-product using gas chromatography–mass spectrometry (GC–MS). Two industrial wax by-products were received from commercial Cannabis processors (labelled wax A and wax B), and were chemically characterised with respect to the major wax components, i.e. n-alkanes, fatty acids, fatty alcohols, sterols, and volatiles (terpenes), and the entrapped cannabinoid fraction. The results are discussed with the focus on identifying fractions with value-adding potential to be recovered from the wax by-product.

2 Materials and methods

2.1 Wax by-products from Cannabis processing

Two wax by-products were acquired from commercial Cannabis processors, labelled wax A and wax B. Wax A was generated from the processing of a CBD-high strain of Cannabis, whereas wax B was generated from the processing of a THC-high strain of Cannabis.

2.2 Standards and reagents

Pure standards for the main classes of compounds, namely long-chain alkanes, fatty acids, fatty alcohols, sterols, and terpenoids, were employed in this study. A long-chain C21–C30 alkane standard was purchased from Sigma-Aldrich (Johannesburg, South Africa) as a 50 mg/L solution in dichloromethane, along with a pure standard (≥ 99%) of nonacosane (C29). Linoleic acid, palmitic acid, 1-hexacosanol, 1-octacosanol, sitosterol, cholesterol, and stigmasterol were purchased from Sigma-Aldrich (Johannesburg, South Africa) as pure compounds, with purities in the range of 90–99%. ß-Caryophyllene was purchased as a 2000 µg/mL solution in methanol along with ursolic acid (≥ 90%) from Sigma-Aldrich (Johannesburg, South Africa). A mixture of terpenoids, namely myrcene, alpha-pinene, camphene, beta-pinene, limonene, alpha-phellandrene, eucalyptol, gamma-terpinene, terpinolene, linalool oxide, linalool, alpha-terpineol, and alpha-bisabolol (purities ranging from 90 to 99%), were provided by the GC department of the Central Analytical Facility (CAF) at Stellenbosch University, the service lab that performed the GC–MS analyses. Further standards for long-chain alkanes and fatty acids were also provided by CAF. Isotopically labelled analytes for use as internal standards were, however, not available from CAF and were not purchased.

2.3 Determination of residual solvent

Both waxes contained residual solvent from the primary extraction that was carried over into the wax separation in the winterisation stage, with wax B containing more solvent than A, as it was not subjected to an evaporation stage after the winterisation stage by the industrial supplier. Thermogravimetric analysis (TGA) was performed with a TGA 5500 (Waters) on wax A and B to determine the fraction of solvent-free wax. A gas flow rate of 70 mL/min was used for this analysis and the samples were equilibrated at 50 °C for 0.16 min after which it was ramped up to 80 °C at 10 °C/min, where it was kept at isothermal conditions for 2 min. This temperate was chosen as it is above the boiling point temperature of the residual solvent, in this case ethanol, which was 78.4 °C. This was followed by a further increase in temperature to 350 °C at 20 °C/min at which it was kept at isothermal conditions for 2 min again. At this point, the cannabinoids would largely have evaporated, and the remaining mass could be attributed to the wax and ash content. For determination of ash content, the temperature was increased to 850 °C and the final weight was measured. The weight of the sample was continuously recorded to generate the TGA curves. The temperature profile was determined by the boiling points of the various fractions, such as the residual solvent, the cannabinoids, and the wax compounds.

2.4 GC–MS analysis

The characterisation of the wax samples was completed by the Central Analytical Facility (CAF) GC–MS laboratory division of Stellenbosch University. Samples were prepared, as described in the upcoming sections, and the analyses were completed by CAF. The resulting characterisation data were processed to generate the characterisation results. All samples were analysed once for each of the four procedures used.

2.4.1 Sample preparation

Fatty alcohol and sterol analysis

Three millilitres of a saponification reagent was added to approximately 100 mg of sample for the analysis of sterol and fatty alcohols. The samples were incubated in an oven at 70 °C for 1 h for completion of the saponification process. The saponified samples were cooled on ice, followed by the addition of 5 mL of distilled H2O and 2 mL of dichloromethane. The mixture was centrifuged for 5 min to facilitate the separation of the layers. After centrifugation, the bottom organic layer was transferred into a clean vial and dried with Na2SO4 to remove any water. One-hundred microliters of the sample was derivatised with 100 µL pyridine and 30 µL of BSTFA followed with incubation in an oven at 100 °C for 1 h [19].

Fatty acid analysis

For the fatty acid analysis, the samples were derivatised to their methyl-ester derivatives. Approximately 100 mg of the sample was taken up into 1.5 mL of 2:1 (v/v) chloroform and methanol mixture and 3 mL of 20% NaCl was added. Samples were sonicated at 55 °C for 30 min and the layers were separated with centrifugation. The bottom chloroform layer containing the fatty acids was extracted and dried with Na2SO4. Two-hundred microliters of dried sample was transferred to a GC-vial insert and dried under a gentle stream of N2. For the wax samples, 100 µL of the dried sample was diluted with 100 µL of chloroform before drying with N2. Dried samples were then derivatised by adding 170 µL of tert-butyl methyl ether(TBME) and 30 µL of trimethylsulfonium hydroxide (TMSH) [20].

Alkane analysis

One millilitre of hexane was added to 10 and 100 mg of wax and oil samples, respectively, for the analysis of alkanes. The solution was then sonicated for 60 min to extract and then 5 mL distilled H2O was added. After the samples were vortexed, it was centrifuged at 2520 RCF for 3 min and 200 µL of the upper hexane layer was transferred into an insert positioned in a 2-mL vial. The wax samples were diluted 1:1 with hexane [21].

Terpene analysis

Terpenes were analysed by solid phase micro-extraction (SPME) of the sample headspace with a polydimethylsiloxane/divinylbenzene (pink) SPME fibre. Five millilitres of 12% (v/v) alcoholic solution (ethanol in water) was added to approximately 100 mg of sample followed by 5 mL of 20% NaCl solution. The samples were vortexed, positioned on the sample tray, and analysed by SPME–GC–MS [22].

2.4.2 Instrumental parameters

The instrumental parameters for each analysis are displayed by Table 1. Generated data were processed using the chemical software Xcalibur (Thermo Fisher Scientific) and compounds were identified by comparison of the relative retention times to those of available standards, analysing the mass fragmentation patterns, and comparison of mass fragmentation patterns with spectra contained in the NIST library.

The characterisation was done using externally calibrated linear calibration curves and the values for these calibrations have been given in Table 2. A minimum of 6 calibrators were used for each component’s calibration curve. Values are given as mg/L, as generated by the instrument, and was later for each wax sample converted to mg/g from the sample weights. No recovery experiments were performed on these samples, as it was not available at these facilities.

The mass ions monitored during the fatty alcohol and sterol analysis using MS/MS (SRM mode) were given in Table 3. For the fatty alcohol analysis, MRM mode was used with three product ions monitored for each analyte, whereas for the sterol analysis SRM mode was used. For the alkane and terpene analyses scan mode was used with a triple-quadrupole mass spectrometer as the concentrations of these analytes were well above trace levels, and therefore, no issues regarding sensitivity were experienced.

2.5 Cannabinoid quantification

The fraction of cannabinoids present in both wax by-products was characterised through a combination of gravimetric and HPLC analyses. The analysis was performed by the LC department of CAF at Stellenbosch University, which provides cannabinoid analysis as a service, and therefore had standards for cannabinoids available. These standards were not available to be transferred between departments and were therefore not available to be used for GC analysis by the authors.

A known amount of each wax (5.14 g of wax A and 10.04 g of wax B) were dissolved in 100 mL of ethyl acetate and mixed. The mixture was then cooled and centrifuged at − 5 °C, after which the supernatant was taken off and heated until all solvent was boiled off and only the cannabinoid fraction remained. The cannabinoid profile was characterised by HPLC analysis. One-hundred milligrams of each sample was extracted by 2 mL of a methanol and water mixture with a ratio of 80:20 (v/v) methanol to water. The samples were sonicated with an AC-150H sonicator (MRC) for an hour before being centrifuged, after which the supernatant was drawn off and sent for analysis. The analysis was performed on a Synapt G2 instrument (Manufacturer: Waters) using electrospray ionisation. The column used was BEH C18 (Manufacturer: Waters) with dimensions 2.1 × 100 mm and pore size 1.7 µm. The mobile phase used was a mixture of water and acetonitrile, and the ratios are summarised in Table 4.

Standards for CBD, ∆9-THC, and THCA were available, but CBDA was quantified relative to THCA. The R-squared values for these calibrations ranged from 0.9903 to 0.9978, provided by CAF. The highest concentration standard was 33.3 ppm and the samples with higher concentrations were extrapolated. Performance parameters such as calibration range, LOD, LOQ, and injection volume were not provided by CAF as it is proprietary knowledge of the LC department.

3 Results and discussions

This work set out to characterise the by-product waxes formed during cannabinoid extraction, using different chromatographic techniques and methods. Two wax by-products were acquired from commercial Cannabis processers, wax A originating from a high-CBD strain of Cannabis sativa and wax B from a high-THC strain. It was expected that there would be significant differences in the cannabinoid composition between the waxes as this profile is strain-specific, but all the main lipophilic molecules were expected to be present in both wax samples [8]. The two by-product waxes were substantially different based on preliminary inspection. Wax A was a dark brown, sticky substance with a distinct herbal smell. Wax B was a yellow-green slurry with a faint herbal smell, and further differed from wax A in that it was not subjected to an ethanol evaporation step beforehand by the industrial supplier. TGA analysis showed that wax A had a solvent content of 34.7% (w/w) and wax B contained 69.9% (w/w) solvent. Figure 1 contains the TGA graphs for the two wax samples that underwent the analyses. All component concentrations reported further in this discussion have been normalised to the dry wax (solvent-free) content and are therefore reported as weight of compound to weight of dry wax (mg/g).

3.1 Characterisation results

Separate analyses for the different lipophilic compounds were necessary owing to co-elution of compounds. Initial analyses attempted to separate the fatty acids, fatty alcohols, and sterols in a single analysis; however, significant overlapping of the fatty acids and alkanes occurred, indicative of co-elution. Therefore, the analysis of fatty acids was done separate from the other compounds. The results of the combined analysis are shown in Table 5 and are reported based on a dry, solvent-free wax basis. The compounds characterised, other than the cannabinoid fraction, made up 42.3% (w/w) of wax A and 18.3% (w/w) of wax B. The fractions for n-alkanes, fatty acids, and fatty alcohols were reported to be the majority of identified lipophilic compounds for both wax samples by the different GC–MS methods. The total quantified mass was 87.7% (w/w) for wax A, but only 54.75% (w/w) of wax B was quantified with the same methodology. It was hypothesised that due to the difference in entrained solvent content between the waxes, the higher levels of ethanol in wax B could have influenced the extraction efficiencies of the target components in their respective sample preparations. However, the reported results regarding the cannabinoid content, determined through gravimetric analysis and HPLC, would not have been influenced by this and significant conclusions could be made regarding the identification of potentially valuable fractions within the wax by-product.

The cannabinoid fraction was the most abundant fraction in both waxes, reporting a total fraction of 509.3 mg/g for wax A and 392.6 mg/g for wax B. In wax A, the most abundant cannabinoid was CBDA (314.8 mg/g) followed by the neutral form CBD (119.5 mg/g). For wax B, the most abundant cannabinoid was THCA (266.3 mg/g) and relatively high amount of the neutral form ∆9-THC (114.0 mg/g) was also reported. Cannabinoid products have high market value (CBD distillates sell for USD 3000 per kg CBD and isolates sell for USD 1000 per kg CBD [8]) and combined with their high concentration in the wax by-product makes this fraction very attractive as a potential target fraction for recovery. Suitable pathways for the recovery of the cannabinoids from the wax waste are, however, lacking in the current scientific and patent literature and further research in the development of such a process is required [23]. A previous study also reported high levels of cannabinoids in the wax by-product, at 416.6–463.7 mg/g [7], indicating that significant entrainment of cannabinoids during the removal of the wax by-product is a general concern for commercial Cannabis processing.

The fatty acid profile was significantly different between the two waxes. The chromatogram of this analysis is provided in Fig. 2. Wax A reported a total fraction of 172.2 mg/g and B, 12.02 mg/g. The major fatty acids present in wax A were palmitic acid (C16:0, 23.19 mg/g), oleic acid (C18:1n9c, 18.83 mg/g), linoleic acid (C18:2n6c, 68.46 mg/g), and α-linolenic acid (C18:3n3, 39.53 mg/g). The same fatty acids were also detected in wax B but were quantified in lower amounts. The major fatty acid in wax B was α-linolenic acid (C18:3n3) with a concentration of 3.011 mg/g. α-Linolenic acid is a highly favourable fatty acid used in cosmetics as it cannot be synthesised naturally in animals. It is often used as an emollient where it serves a hydrating purpose [24].

Previous literature reported that the fatty acids were only present in trace amounts [7], but a major difference done in this work was the individual fatty acid analysis, due to high levels of co-elution with other components. As a result, this work was able to quantify the fatty acids at more accurate levels than trace amounts, which is important for subsequent investigations into potential valorisation of this by-product.

The n-alkane fraction was composed of chain lengths C20 up until C33. The chromatogram for this analysis is provided in Fig. 3. As was expected from plant waxes, the odd-numbered chain lengths were dominant with only a few even-numbered chain lengths detected in both samples [25,26,27]. The n-alkane fraction was reported as 135.1 and 54.55 mg/g for wax A and B, respectively. The major alkanes detected for both waxes were C29 (n-nonacosane), followed by C27 (n-heptacosane) and C31 (n-hentriacontane). Wax A contained 52.19 mg/g and wax B 24.47 mg/g of n-nonacosane. The highest chain length quantified in the sample was C33 (n-tritriacontane). Long-chain alkanes are the main compound class in paraffinic waxes [28] and the large fraction in the Cannabis wax can therefore be utilised as a potential natural source of paraffinic wax. The range of chain lengths quantified in this work was comparable to what was reported previously on Cannabis wax. In both cases, the odd-numbered chain lengths were dominant and ranged from C21 to C33 in this work and C25 to C37 for the results previously reported in literature [7]. In both analyses C29 (nonacosane) was the most abundant alkane. The relative total alkane fraction quantified in this work was however much less than reported by literature (290.7–291 mg/g) [7].

The fatty alcohols reported a total fraction of 24.68 mg/g for wax A and 36.10 mg/g for wax B. The chromatogram for this analysis is provided in Fig. 4. The dominant chain length in wax A was C28 (1-octacosanol) which had a concentration of 14.23 mg/g. C26 was dominant in wax B and had a reported concentration of 18.88 mg/g. Fatty alcohols are commonly used in lotions, moisturisers, creams, and other personal care products. Its main contribution to these products is acting as an emulsifier, prohibiting the separation of oil and other liquids [29].

The low levels of fatty alcohols in the wax by-product would, however, not be economically feasible to recover specifically, and therefore, the wax would likely not be a viable source of these components. As with the fatty acids, the fatty alcohol fraction was reported only in trace amounts in a previous study [7], which reported on the free fatty alcohol content. In this work, the fatty alcohol fraction was quantified as both the free fatty alcohols and the released fatty alcohol chains from the transesterification of the wax esters. It is therefore highly likely that the free fatty alcohol concentration in the wax by-product is relatively low in comparison to the fatty alcohols bound in the wax esters.

The sterol fraction was relatively small, with a total of 5.946 mg/g and 0.273 mg/g for wax A and B, respectively. ß-Sitosterol was the major compound in both waxes, a high-value compound that has been found to lower cholesterol and reduce the risk of certain cancers when used in medicine [30]. Stigmasterol was detected in lower amounts than ß-sitosterol and cholesterol was detected in wax A only, but at a very low level of 0.0003 mg/g and could therefore be assumed to be negligible. Although these components have high commercial value, the low levels in which they are present in the Cannabis wax by-product would likely not be commercially worthwhile to recover.

The terpenoid fraction composed largely of monoterpenes with a few terpenoids and sesquiterpenoids also reported in detectable quantities, and the chromatogram for this analysis is provided in Fig. 5. The total fraction was reported as 0.954 µg/g for wax A and 1.519 µg/g for wax B. The major monoterpenoid compounds were α-pinene, ß-pinene, α-phellandrene, and limonene. Myrcene, a common monoterpenoid found in Cannabis, was also detected in lesser amounts. In the terpenoid fraction the major compounds were linalool, α-eudesmol, and eudesm-4(14)-en-11-ol. A concentration of 0.061 µg/g and 0.114 µg/g for wax A and B, respectively, was reported for (-)-trans-caryophyllene, another common terpenoid in Cannabis. There was a significant difference in the concentrations of the terpenoid fraction when compared to a previous study, where it was reported as 241.1–302.2 mg/g [7]. The major terpenoids reported previously were p-cymene (33.2–51.5 mg/g) and (-)-trans-caryophyllene (59.0–72.2 mg/g) [7], both of which were only quantified in trace amounts in this work. The reasons for the differences in terpenoid amount and profile between the current and prior work are not apparent, but may be because the terpenoid profile of Cannabis is strongly affected by the Cannabis strain [31] or due to the different industrial and sample preparation prior to wax analysis.

Another major compound class that is commonly found in plant waxes are wax esters, products of an esterification reaction between a fatty acid and a fatty alcohol. These compounds are typically very large organic molecules, with carbon chain lengths ranging between C40 and C54, and due to their sizes are difficult to analyse using GC, relating to column elution and limited volatility. These compounds can be accounted for through analysis of both derivatised and underivatised samples from fatty alcohol and fatty acid analysis [32]. A previous study that investigated the composition of a lipophilic extract from hemp reported the wax ester fraction to be up to 11.7% (w/w) of this extract [33], and therefore, it was attempted to account for the wax esters through the fatty acid and fatty alcohol analysis. During the fatty alcohol analysis, saponification of the samples resulted in the transesterification of the wax esters and the release of the fatty alcohol. The free fatty alcohols as present in the wax, along with the fatty alcohols from the wax esters, were then further derivatised and quantified as a total fatty alcohol fraction. During the fatty acid analysis, derivatisation of the fatty acids to their methyl ester forms was also a form of transesterification, resulting in the release and derivatisation of the fatty acid chain from the wax ester. Therefore, the wax esters were indirectly accounted for through the release and quantification of the respective fatty acids and fatty alcohols through.

Whilst a significant portion of these waxes have been positively identified, a fraction remains unidentified. A possible explanation regarding the unidentified mass can be attributed to abundant compounds that fell beyond the methods of analysis. These could include various fatty alcohols and fatty acids for which chemical standards were not acquired and therefore were not quantified. Another compound class that was not investigated was aldehydes, which have been reported as present in substantial amounts in other plant waxes [32,33,34,35]. As the wax by-product was removed from the initial ethanol extract though filtration, plant material from the raw Cannabis entrained in the initial extraction likely also formed part of the removed wax. This insoluble material was assigned to the ash content fraction and was found to be 30.2 mg/g for wax A and 51 mg/g for wax B.

From evaluation of the results generated by this work and literature, it is evident that the composition of the waxes is dependent on upstream processing, specifically the type of primary extraction done and solvent evaporation, as well as the source biomass and strain of C. sativa used. Major differences were reported between the composition of wax A and wax B due to difference in processing and strains used. It is therefore clear that there will be inherent variability in the composition of wax by-products from C. sativa, highlighting the importance of establishing robust analysis methods, and of conducting and publishing this analysis on various samples, so that sensible ranges can be established.

4 Conclusions

The work demonstrates a combination of GC–MS and HPLC methods to determine the composition of two wax by-products from commercial Cannabis processing. The major finding of this study was that a significantly large fraction of cannabinoids was entrained in the wax by-product, determined to be 509.3 mg/g for wax A and 392.6 mg/g for wax B, indicating a prominent loss of value during the initial stages of commercial Cannabis processing. This fraction was also determined to be the most abundant fraction in both these waxes. From both research and economic perspectives, it would be advantageous to recover the cannabinoids from wax and prevent the loss of these valuable components. This would furthermore provide a potential valorisation application for the wax by-products, which is currently not described in literature. The characterisation also identified large amounts of fatty acids and n-alkanes, which have found application in cosmetics where they serve as the base or a binder in numerous products. Refined Cannabis wax can potentially also find application in the cosmetics field based on this compositional result. When compared with current literature, significantly different values were reported for both the fatty acid and terpenoid fractions, potentially due to the improved method used in this work. Only trace amounts were reported for the fatty acid fraction in literature, but these were found to be the second most abundant fraction for wax A in this work.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- CAGR:

-

Compound annual growth rate

- CBD:

-

Cannabidiol

- CBDA:

-

Cannabidiolic acid

- DCM:

-

Dichloromethane

- GC:

-

Gas chromatography

- LC:

-

Liquid chromatography

- MRM:

-

Multiple reaction monitoring

- MS:

-

Mass spectrometry

- SC-CO2 :

-

Supercritical carbon dioxide

- SPME:

-

Solid phase micro-extraction

- SRM:

-

Selective reaction monitoring

- TBME:

-

Tert-butyl methyl ether

- TGA:

-

Thermogravimetric analysis

- THC:

-

Tetrahydrocannabinol

- THCA:

-

Tetrahydrocannabinolic acid

- TLC:

-

Thin layer chromatography

- TMSH:

-

Trimethylsulfonium hydroxide

References

JH Cherney, Small E (2016) Small, industrial hemp in North America: production, politics and potential. Agronomy 6(4):58. https://doi.org/10.3390/agronomy6040058

Ugalmugle S, Swain R (2021) Cannabidiol (CBD) market size by product (oil, tinctures, suppository, transdermal patches, isolates, tablet, capsules, vape oil, creams and roll-on), by application (anxiety/stress, sleep/insomnia, chronic pain, migraine, skin care, seizures, joint pain & inflammation, neurological conditions), by Route of administration (oral, topical, inhalation, transdermal patches, rectal, sublingual), by Source (Marijuana, Hemp), by distribution channel (online, offline {hospital pharmacy, retail stores}), COVID-19 impact analysis, regional outlook, growth potential, price trends, competitive market share & forecast, 2021–2027. Global market insights

Grijó DR, Vieitez Osorio IA, Cardozo-Filho L (2018) Supercritical extraction strategies using CO2 and ethanol to obtain cannabinoid compounds from Cannabis hybrid flowers. J CO2 Util 28:174–180. https://doi.org/10.1016/j.jcou.2018.09.022

Valizadehderakhshan M, Shahbazi A, Kazem-Rostami M, Todd MS, Bhowmik A, Wang L (2021) Extraction of cannabinoids from Cannabis sativa L. (Hemp)—review. Agriculture 11(5):384. https://doi.org/10.3390/agriculture11050384

Baldino L, Scognamiglio M, Reverchon E (2020) Supercritical fluid technologies applied to the extraction of compounds of industrial interest from Cannabis sativa L. and to their pharmaceutical formulations: a review. J Supercrit Fluids 165:104960. https://doi.org/10.1016/j.supflu.2020.104960

Moreno T, Montanes F, Tallon SJ, Fenton T, King JW (2020) Extraction of cannabinoids from hemp (Cannabis sativa L.) using high pressure solvents: an overview of different processing options. J. Supercrit. Fluids 161:104850. https://doi.org/10.1016/j.supflu.2020.104850

Leyva-Gutierrez F, Munafo JP, Wang T (2020) Characterization of by-products from commercial cannabidiol production. J Agric Food Chem 68(29):7648–7659. https://doi.org/10.1021/acs.jafc.0c03032

Noppawan P et al (2022) Effect of harvest time on the compositional changes in essential oils, cannabinoids, and waxes of hemp (Cannabis sativa L.). R Soc Open Sci 9:6. https://doi.org/10.1098/rsos.211699

Montserrat-De La Paz S, Marín-Aguilar F, García-Giménez MD, Fernández-Arche MA (2014) Hemp (Cannabis sativa L.) seed oil: analytical and phytochemical characterization of the unsaponifiable fraction. J Agric Food Chem 62(5):1105–1110. https://doi.org/10.1021/jf404278q

Caligiani A, Malavasi G, Palla G, Marseglia A, Tognolini M, Bruni R (2013) A simple GC-MS method for the screening of betulinic, corosolic, maslinic, oleanolic and ursolic acid contents in commercial botanicals used as food supplement ingredients. Food Chem 136(2):735–741. https://doi.org/10.1016/j.foodchem.2012.08.011

Liu D et al (2015) Analysis of cuticular wax constituents and genes that contribute to the formation of ‘glossy Newhall’, a spontaneous bud mutant from the wild-type ‘Newhall’ navel orange. Plant Mol Biol 88(6):573–590. https://doi.org/10.1007/s11103-015-0343-9

Belge B, Llovera M, Comabella E, Graell J, Lara I (2014) Fruit cuticle composition of a melting and a nonmelting peach cultivar. J Agric Food Chem 62(15):3488–3495. https://doi.org/10.1021/jf5003528

Delange DM, Rico CLM, Leyes EAR, Canavaciolo VG (2013) Determination of sterol and fatty alcohols in unsaponifiable matter of Roystonea regia fruits oil. J Med Plants Res 7(37):2736–2740. https://doi.org/10.5897/JMPR12.1004

Awasthi MK et al (2020) Refining biomass residues for sustainable energy and bio-products: an assessment of technology, its importance, and strategic applications in circular bio-economy. Renew Sustain Energy Rev 127:109876. https://doi.org/10.1016/j.rser.2020.109876

Şen AU, Correia R, Longo A, Nobre C, Alves O, Santos M, Gonçalves M, Miranda I, Pereira H (2022) Chemical composition, morphology, antioxidant, and fuel properties of pine nut shells within a biorefinery perspective. Biomass Conv Biorefy 1–3. https://doi.org/10.1007/s13399-022-03605-8

Gutiérrez A, Del Río JC, González-Vila FJ, Martín F (1998) Analysis of lipophilic extractives from wood and pitch deposits by solid-phase extraction and gas chromatography. J Chromatogr A 823(1–2):449–455. https://doi.org/10.1016/S0021-9673(98)00356-2

Rockwood AL, Kushnir MM, Clarke NJ (2018) Mass spectrometry. In: Rifai N, Horvath AR, Wittwer CT (Eds.), Principles and applications of Clinical Mass Spectrometry, Elsevier, London, pp. 33–65. https://doi.org/10.1016/B978-0-12-816063-3.00002-5

Leide J, Hildebrandt U, Reussing K, Riederer M, Vogg G (2007) The developmental pattern of tomato fruit wax accumulation and its impact on cuticular transpiration barrier properties: effects of a deficiency in a β-ketoacyl-coenzyme A synthase (LeCER6). Plant Physiol 144(3):1667–1679. https://doi.org/10.1104/pp.107.099481

Kaseke T, Opara UL, Fawole OA (2021) Quality and antioxidant properties of cold-pressed oil from blanched and microwave-pretreated pomegranate seed. Foods 10(4):712. https://doi.org/10.3390/foods10040712

Firl N, Kienberger H, Rychlik M (2014) Validation of the sensitive and accurate quantitation of the fatty acid distribution in bovine milk. Int Dairy J 35(2):139–144. https://doi.org/10.1016/j.idairyj.2013.11.007

Das S, Koner A, Barik A (2019) A beetle biocontrol agent of rice-field weeds recognizes its host plants by surface wax long-chain alkanes and free fatty acids. Chemoecology 29(4):155–170. https://doi.org/10.1007/s00049-019-00285-1

Moloinyane S, Nchu F (2019) The effects of endophytic Beauveria bassiana inoculation on infestation level of planococcus ficus, growth and volatile constituents of potted greenhouse grapevine (Vitis vinifera L.). Toxins (Basel) 11(2):1–13. https://doi.org/10.3390/toxins11020072

Duminy JH, Goosen N, Pott R, van Rensburg E (2023) Development of a solvent screening methodology for cannabinoid recovery from a wax by-product via recrystallization. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-023-04063-6

Muhamad II, Hassan ND, Mamat SN, Nawi NM, Rashid WA, Tan NA (2017) Extraction technologies and solvents of phytocompounds from plant materials: physicochemical characterization and identification of ingredients and bioactive compounds from plant extract using various instrumentations. In ingredients extraction by physicochemical methods in food, Elsevier Inc., pp 523–560

von Wettstein-Knowles P (2012) Plant waxes, in encyclopedia of life sciences, pp. 1–13. https://doi.org/10.1002/9780470015902.a0001919.pub2

Manheim BS, Mulroy TW (1978) Triterpenoids in epicuticular waxes of Dudleya species. Phytochemistry 17(10):1799–1800. https://doi.org/10.1016/S0031-9422(00)88704-X

Sin EH (2012) The extraction and fractionation of waxes from biomass, Ph.D. dissertation, Dept. Chem., University of York, York

Palou A et al (2014) Characterization of the composition of paraffin waxes on industrial applications. Energy Fuels 28(2):956–963. https://doi.org/10.1021/ef4021813

National Center for Biotechnology Information (2021) Cetostearyl alcohol. PubChem Compound Summary for CID 62238. https://pubchem.ncbi.nlm.nih.gov/compound/Cetostearyl-alcohol. Accessed 13 Apr 2021

Wang H, Wang Z, Zhang Z, Liu J, Hong L (2023) β-Sitosterol as a promising anticancer agent for chemoprevention and chemotherapy: mechanisms of action and future prospects. Adv Nutr. https://doi.org/10.1016/j.advnut.2023.05.013

Sommano SR, Chittasupho C, Ruksiriwanich W, Jantrawut P (2020) The Cannabis terpenes. Molecules 25(24):1–16. https://doi.org/10.3390/molecules25245792

Marques G, del Río JC, Gutiérrez A (2010) Lipophilic extractives from several nonwoody lignocellulosic crops (flax, hemp, sisal, abaca) and their fate during alkaline pulping and TCF/ECF bleaching. Bioresour Technol 101(1):260–267. https://doi.org/10.1016/j.biortech.2009.08.036

Gutiérrez A, Del Río JC (2005) Chemical characterization of pitch deposits produced in the manufacturing of high-quality paper pulps from hemp fibers. Bioresour Technol 96(13):1445–1450. https://doi.org/10.1016/j.biortech.2004.12.008

Kolattukudy PE, Buckner JS, Liu T-YJ (1973) Biosynthesis of secondary alcohols and ketones from alkanes. Arch Biochem Biophys 156(2):613–620

Ahmad HM, Rahman MU, Ali Q, Awan SI (2015) Plant cuticular waxes: a review on functions, composition, biosyntheses mechanism and transportation. Life Sci J 12(4s):60–67

Acknowledgements

The Cannabis wax, used as feedstock in this work, was provided by GES Labs (Cape Town, South Africa). The instrumentation and materials used for the analysis were provided by the Central Analytical Facility at Stellenbosch University.

Funding

Open access funding provided by Stellenbosch University.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Jan-Hendrik Duminy. The first draft of the manuscript was written by Jan-Hendrik Duminy and all authors commented on subsequent versions of the manuscript. All authors read and approved the final manuscript.

Jan-Hendrik Duminy: conceptualisation, investigation, writing — original draft. Neill Goosen: writing — review and editing, supervision, project administration, funding acquisition. Robert Pott: writing — review and editing, supervision, project administration, funding acquisition. Eugene van Rensburg: writing — review and editing, supervision, project administration, funding acquisition. William Arries: methodology, investigation, resources, writing — review and editing. Lucky Mokwena: methodology, investigation, resources. Lindani Kotobe: methodology, investigation, resources.

Corresponding author

Ethics declarations

Ethical approval

This declaration is not applicable to this manuscript.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Duminy, JH., Goosen, N., van Rensburg, E. et al. Application of different chromatographic techniques to characterise wax by-products generated during cannabinoid extraction. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04448-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04448-7