Article: DB Schenker Product Show: „Creating digital added value“

Innovative solutions strengthen supply chains and make them more sustainable • Digitalisation in land transport • Virtual warehouse for spare parts • Inspection of returns with VR glasses • VoloDrone at display

DB Schenker ensures the supply of goods, industrial goods and medical products for companies and consumers worldwide, even in difficult times. The use of new, innovative and digital products in the operational business makes supply chains more stable, improves service for customers and supports environmental and climate protection.

On Wednesday, Jochen Thewes, CEO of DB Schenker, presented the company's latest innovations at its first product show in Frankfurt.

More transparent, efficient, sustainable: In the Digital Control Room of Air and Ocean Freight

The framework conditions for global supply chains are changing rapidly. Currently, they are characterized by a period of enormous uncertainty and volatility. Disruptions in supply chains triggered by, for example, pandemic port closures, the general shortage of qualified staff, extreme weather, but also by over-all cost increases in the energy and transport sector, are creating changed market conditions. Supply chains need to be agile, resilient, and supported by IT solutions to survive in this agile environment.

DB Schenker’s Intercontinental Supply Chain Solutions (ISC) experts are driving the digitalization of supply chains with holistic IT platforms and processes. These digital solutions enable optimized transport management as well as collaborative processes between the customer, their supply chain partners and DB Schenker. Overall, the supply chain becomes more resilient and agile.

The digital solutions are characterized by the following advantages:

- All partners — from the customer to DB Schenker as logistics service provider to the carrier — are integrated along the customer-specific supply chain on a central platform.

- This central platform enables a holistic, transparent overview of the supply chain with real-time data down to the product level. There is round-the-clock tracking capability for all partners.

- Big Data supports data-based decision-making. Forecasting tools combined with IoT (Internet of Things) solutions generate more accurate container arrival times and live status updates of shipments. The supply chain can be continuously tracked and optimized – including CO2 emissions.

ISC Digital Solutions

More information about Intercontinental Supply Chain Solutions can be found on the DB Schenker website.

DB Schenker digitalizes Europe's leading land transport network

At the Control Tower in Frankfurt, DB Schenker's land transport experts have a real-time view of the whole of Europe: 430 terminals, 2,000 daily connections, more than 40,000 partner companies. It enables DB Schenker’s team to steer, optimize, monitor and maintain our linehaul network throughout Europe.

The system, called LiNeS, is one of numerous network and platform applications that have been created in recent years in cooperation between land transport experts and DB Schenker's inhouse IT. These include the carrier platform Drive4Schenker and the new Transport Management System, the deployment of which is currently being prepared throughout Europe.

This shows: The future of land transport is digital - and with the sensible use of digital technologies, it will become increasingly efficient, economical, smarter and more climate-friendly.

For more information, visit the land transport section of the DB Schenker website.

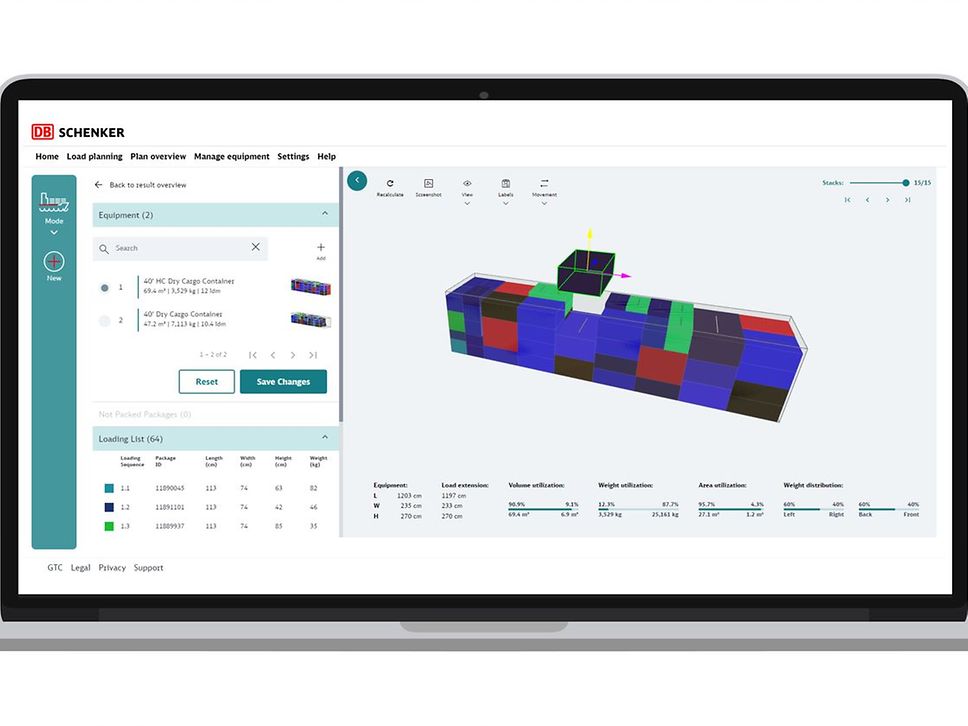

Digital Buzzword AI - Hot or Not? A Critical Fact Check on Artificial Intelligence for Logistics

Artificial intelligence - what can this buzzword actually do for the logistics industry? For DB Schenker, AI is less science fiction but adds real value in day-to-day business. As a tool, it imitates human abilities, but does not replace them. Rather, it helps to make fact-based decisions and thus stabilizes supply chains and increases efficiencies in transport. At DB Schenker, artificial intelligence finds points of contact, for example, in the interface with the customer (e.g. with dynamically optimized offers and prices), within the forwarding process (e.g. through transparency and forecasting capabilities), and in the optimization of transports (e.g. in network design and optimization) and warehousing processes (e.g. in demand and sales forecasts).

Three concrete examples of the use of AI at DB Schenker:

- Mathematical optimization solves common problem areas in logistics. It can optimize ZIP code catchment areas, tours, and container loads so that transports can be bundled.

- In selected warehouses and terminals, process flows are recorded in real time using computer vision technology to better understand the status quo and be able to control operational processes more precisely. For example, objects can be identified and tracked, and utilization analyses can be performed.

- Using natural language processing methods, Schenker can both improve the performance of its chatbots and automatically detect and correct data quality problems.

Since any applied AI is only as good as the data on which it is based, a key area of action for Schenker is to systematically drive forward the availability and quality of data. The decisive factor is above all a pronounced and practiced data culture in the company.

More information on the DB Schenker homepage.

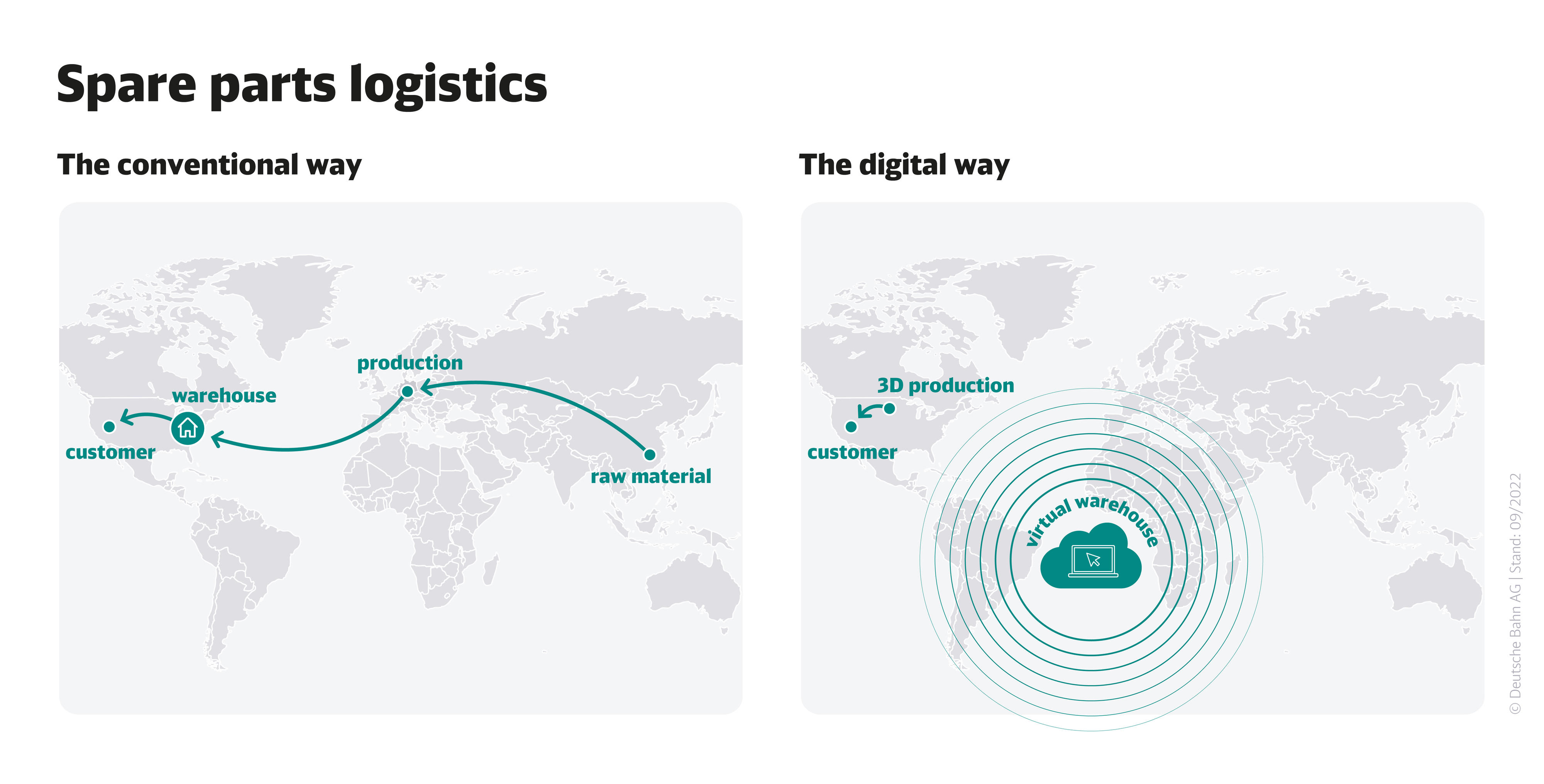

On-Demand Production: Virtual Warehouse with 3D Printing

Digital innovations can help to address many of the numerous challenges global logistics is facing. Spare part deliveries via 3D printing is a new example of how DB Schenker creates real added value for customers.

A virtual warehouse has many advantages: Lead times, logistics costs and also inventory stocks can be drastically reduced. Recent studies assume that up to 10% of spare parts inventories can be produced via additive manufacturing and do not need stockpiling. On top, a virtual warehouse helps to increase part availability and allows to respond more flexibly to unplanned delivery bottlenecks. With additive manufacturing, parts can be produced "on-demand", exactly when they are needed. This eliminates long waiting times and spare parts that are no longer available remain available, which extends the service life of equipment.

Thanks to near-net-shape manufacturing, valuable raw materials are only used for the workpiece that is actually needed. Thanks to a worldwide network of contracted manufacturers, printing can take place close to where it is needed. This saves transport distances, energy and CO2 emissions.

Deutsche Bahn is a pioneer in the additive manufacturing of spare parts and has been actively involved with this digital manufacturing technology for many years. As a global logistics company, Schenker's core competencies lie in the operation of physical warehouses and worldwide supply chains. With Schenker’s new service “On-Demand Production”, customers can benefit from both company’s expertise and receive everything from a single source.

Optimising processes in contract logistics: DB Schenker uses data glasses to inspect returns in virtual space

Faster, more efficient, and more sustainable – DB Schenker uses virtual spaces for logistical processes in its physical warehouses. Employees at the contract logistics warehouse in Neu-Isenburg use data glasses to inspect returns in a virtual space. Inspections that used to require customer experts to be physically present at the location can now be performed via remote video-streaming. To make this possible, Schenker has implemented augmented reality (AR) glasses at its logistics center.

The new process has enabled DB Schenker to reduce turnaround times for returns of around 80 percent of incoming items from an average of 180 days to 7-14 days. Additionally, carbon dioxide emissions caused by long distance travel are significantly reduced. Whereas before customer engineers had to fly in to inspect parts (often from overseas), logistics experts in Neu-Isenburg are now virtually connected with engineers from over thousands of kilometers away.

To perform a virtual inspection a Schenker employee connects to the customers's engineer via hands-free video streaming using AR glasses. The engineer can remotely inspect the product from the employee's perspective, give instructions and set markers or display documents via the application. The content is then displayed to the employee as a hologram in real time. The AR headset was introduced at the Neu-Isenburg site in mid-2021 and has been in regular use since then.

Stable supply chains in times of pandemic: Protecting employees with modern sensor technology

Covid-19 has presented a major challenge to the logistics industry – a challenge during which the health and safety of employees has always been and still is a top priority for DB Schenker. If supply chains are to remain stable, employees must first be protected. To achieve this, DB Schenker introduced a hygiene concept involving modern sensor technology at its Neu-Isenburg site in order to keep all 100 warehouse employees as safe as possible, even during the pandemic. Within the warehouse, which covers around two soccer fields in size, sensors help employees to keep a safe distance from other colleagues.

The essential piece of the solution is a small, portable device: weighing a mere 15 grams, the “KINEXON SafeTag” can be worn as a wristband or attached to work clothing. It continuously measures the distance between employees with an accuracy of up to 10 centimeters and gives an acoustic and visual warning sign if the minimum distance of 1.5 meters to another person is not maintained.

Additionally, in the event of an infection, critical contacts can be identified within 15 minutes, making it possible to quickly inform affected employees. The data generated in this process is accepted by the local health department as the basis for further protective measures. Meaning: In case of infection, only relevant contacts need to go into isolation.

By introducing KINEXON SafeZone DB Schenker protects its employees and is able to maintain 24/7-business at its Neu-Isenburg site.

Innovative training technology: Training forklift drivers in virtual reality

Authentic training that does not disrupt operations – DB Schenker uses virtual reality technology to train forklift drivers. The application enables users to practice operating the forklift in digital representations of real locations, helping them gain a better sense for safety in the process. DB Schenker developed the prototype of the VR training system in collaboration with the Fraunhofer Institute for Material Flow and Logistics IML in the EnterpriseLab for Logistics and Digitalization.

The simulator consists of a reconstructed forklift control system and VR glasses through which users can dive into and navigate through a virtual storage environment. Driving through rows of shelves, storing and reloading goods, interacting with relevant items – users train the same processes as they would in a physical warehouse. Unlike at a real location, however, the application can also simulate exceptional and hazardous situations, enabling users to train under special circumstances that would otherwise be difficult to practice in the real world.

Forklift training in virtual reality

By implementing the innovative training system, DB Schenker actively improves safety at its locations: aspiring forklift drivers can familiarize themselves with the actual storage environment in advance and practice relevant safety measures. And forklift drivers that are already working at the locations can use the system to refresh their training, promoting responsible behaviour and reducing the risk of forklift accidents. Furthermore, virtual forklift training is another step towards digitizing the world of work. This is something employees enjoy as a survey conducted among those who have completed a VR forklift training has shown.

DB Schenker first launched the simulator as a pilot project in 2019 at the Tilburg Logistics Center in the Netherlands, where it was used to train forklift drivers. Since then, the system has also been used in Cairo. Further roll-outs at other DB Schenker locations worldwide are planned.

Partnership of Volocopter and DB Schenker

Since mid-2019, Volocopter and DB Schenker have been working together on the further development of the heavy-duty drone "VoloDrone" for specific application areas of drone services in logistics.

At the beginning of 2020, DB Schenker joined the Urban Air Mobility company as a strategic investor. The aim is to use drone operations to expand the existing logistics infrastructure for land or sea transport and to create completely new supply chains and transport routes.

As part of the collaboration with DB Schenker, the drone completed its first public flight in October 2021: for this, the electric cargo drone was equipped with a loading box between the landing frame to transport cargo on a Euro pallet to a DB Schenker Cargo Bike. After safe landing of the VoloDrone and successful handover, a cargo bike brought its delivery to its final destination. The test flight reached a maximum altitude of 22 meters.

As early as July 2021, DB Schenker and Volocopter had developed an operational plan for the operation of electric cargo drones in logistics. This was based on a study conducted jointly with the Fraunhofer Institute for Material Flow and Logistics. The simulation conducted by the Volocopter, DB Schenker and Fraunhofer research teams included the study of ground processes for coding goods, evaluation of safe cargo loading of goods, automated drone delivery services by autonomous vehicles and logistics-specific necessary pre-flight checks. In addition, safe, standardized procedures were identified for on-site personnel to cover transportation and loading processes, as well as VoloDrone flight preparations.

The VoloDrone is an unmanned, all-electric cargo drone designed to transport ISO pallets of all sizes weighing up to 200 kilograms over a range of 40 kilometers. This electric vertical takeoff and landing aircraft is designed for versatile operations in various industries. The aircraft has 18 rotors and motors for propulsion. The drone is 9.15 meters in diameter, 2.15 meters high and has a maximum takeoff weight of 600 kilograms. In the future, the VoloDrone will be fully electric and capable of flying autonomously out of sight of the pilot.

Volocopter in action

Partnership with Avatour to Pioneer VR Warehouse Tours: Real-time 360° technology helps drive innovation and sustainability

DB Schenker recently underlined its ambition to become front runner in its industry by partnering with Avatour to develop a true alternative: enabling virtual warehouse tours, offering a 360° perspective with real time video.

“The partnership with Avatour offers us a new dimension of digitalisation in the contract logistics business,” said Todd Starbuck, EVP Business Development, Solution Design and Customer Management. “It is essential for us and our operations to stay close to our customers,” he added.

DB Schenker selected Avatour because of its unique digital platform, helping them to:

- Gain visibility and grant customer access to its operations

- Improve on-site performance with remote training and auditing

- Keep people safe and secure while providing support when working from home

- Save millions in travel expenses, not to mention lost productivity

- Reduce CO2 emissions by avoiding travel, thereby helping the environment

As an example of savings – each DB Schenker warehouse is visited at least once per year by five employees and partners. Domestic travel alone accounts for millions of dollars of travel expenses and significant CO2 emissions.

“We’re excited to help DB Schenker realize a future beyond distance,” said Avatour’s founder and CEO Devon Copley. “Avatour’s technology is a category-defining platform helping companies reimagine their traditional ways of doing business. Ultimately, the results we see are good for the company, its people, and the environment,” he added.

Cargo-Bikes and electric trucks: Fast forward to emission-free urban logistics

Sustainable mobility is becoming increasingly important in the metropolitan regions. Already today, DB Schenker offers CO2-free deliveries in more than 60 European cities.

More than 140 electric-driven vehicles are in DB Schenker’s urban fleet, 60 Cargo-Bikes are used in 24 European cities. With the XXL cargo Bike, servicing customers in Hamburg and soon in Coburg, there even is one extraordinarily powerful e-bike delivering three Euro pallets and up to 500 kilograms of cargo load on the last mile.

Of all European countries, France and Norway are using the biggest number of green vehicles, with 62 and 42 vehicles respectively. At Oslo City Hub, DB Schenker is using 18 eTrucks and 3 eBikes – making it DB Schenker’s first entirely CO2-neutral City hub.

DB Schenker is expanding its fleet of electrically powered vehicles through different partnerships. For example, there are over 40 FUSO eCanter, a Daimler trucks brand, in eleven European countries.

DB Schenker also became the first customer worldwide to receive the delivery of the first battery-electric Mercedes-Benz eActros as a series-production vehicle. The global logistics services provider will be using the 19-ton truck for general cargo deliveries in urban logistics operations. With the eActros, DB Schenker is adding another vehicle model to its sustainable fleet and taking another important step toward climate-neutral logistics.

And most recently, DB Schenker has pre-ordered 1,500 Volta Zero Trucks, full-electric commercial vehicles. This is the most significant order for large zero-emission trucks in Europe to date.

With over 150 years of logistics experience, the company supports industry and trade in the global exchange of goods in land transport, air and sea freight, contract logistics and supply chain management.

More pictures from the product conference can be found in the DB Mediaportal.