Scientists from Swansea University and the University of Surrey in the United Kingdom have developed a flexible thin-film cadmium telluride (CdTe) solar cell for use in ultra-thin glass for space applications. They have tested the performance of the cell for more than three years on a satellite in low earth orbit, in cooperation with the U.K. and Algerian space agencies.

“The cell may also be used for terrestrial applications,” researcher Dan Lamb told pv magazine. “For our technique of manufacturing the CdTe onto ultra-thin glass, the solar cell could be used where light weight and flexibility are key, as for example, in building-integrated photovoltaics (BIPV) and unmanned aerial vehicles.”

Lamb said that CdTe cells offer the potential for significant cost savings over well-established multi-junction space cells. For terrestrial use, where CdTe PV is already highly cost-competitive, additional savings could be achieved through reduced transportation costs of the lightweight technology.

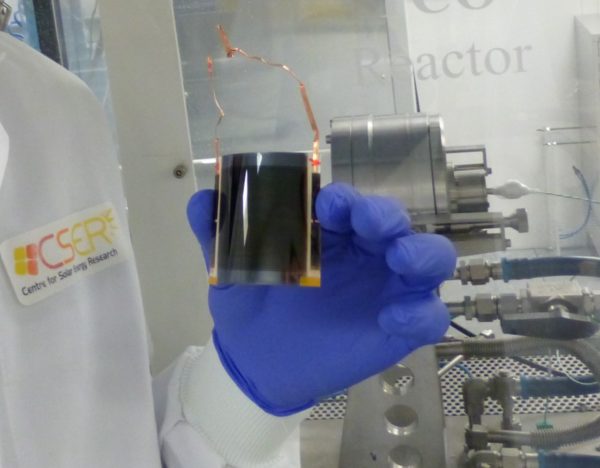

Image: Swansea University

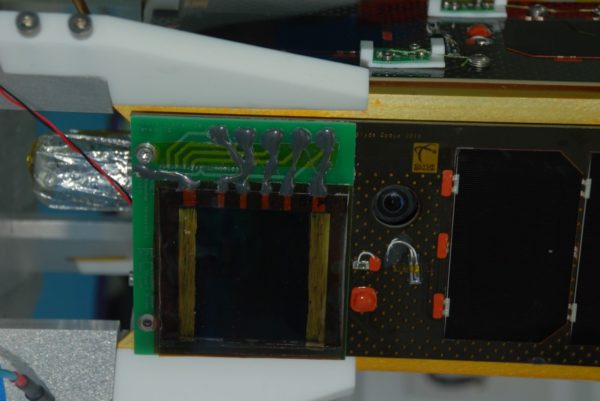

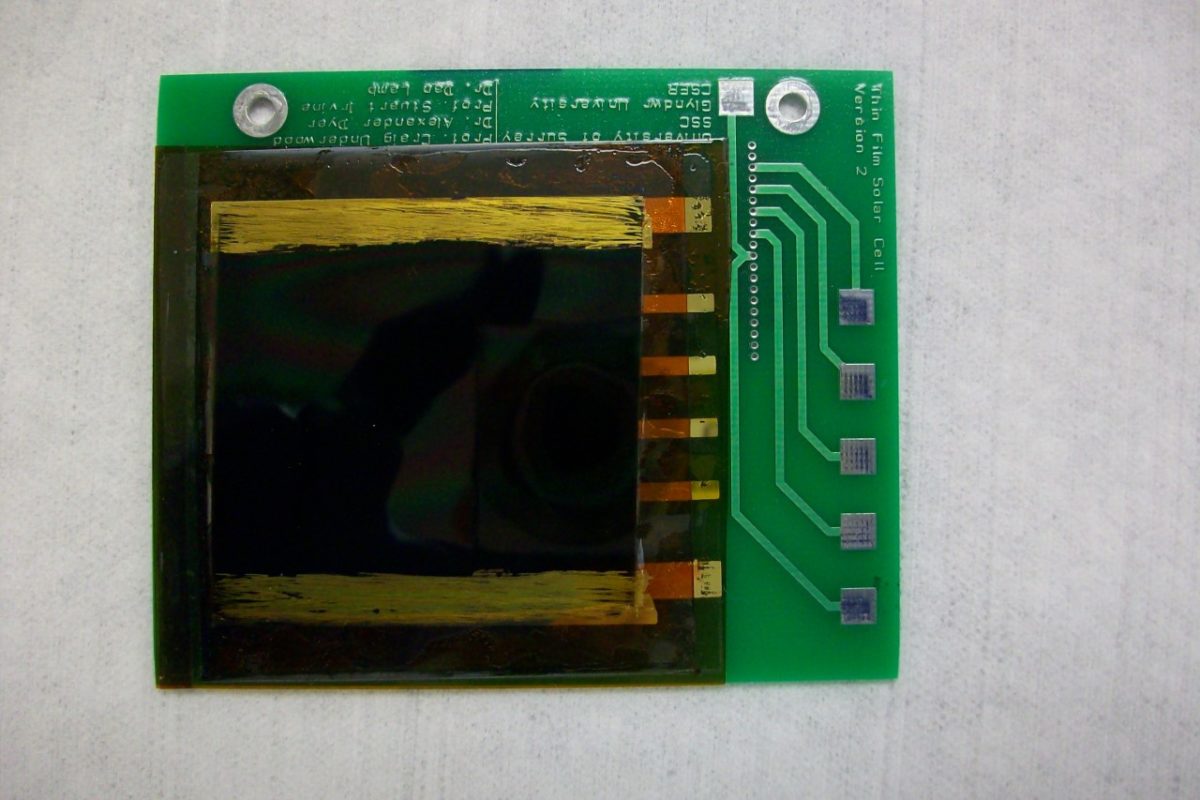

The experimental cell for the space mission was built by depositing the CdTe material through metalorganic chemical vapour deposition (MOCVD) onto a radiation hard glass, with a thickness of just 100 micron. The glass is a cerium-doped aluminosilicate product supplied by U.K.-based Qioptiq Space Technology. To achieve a robust structure and allow for electrical measurements, the solar cell was then laminated to a printed circuit board.

The cell is based on a number of semiconducting thin films. The first layer deposited onto the ultra-thin glass substrate is a transparent conducting electrode (TCE) made of aluminum-doped zinc oxide. Then, the scientists used a layer of zinc oxide to reduce micro shunts, followed by a cadmium zinc sulfide n‐type layer, and finally, an arsenic‐doped CdTe p‐type layer. The researchers used four cells measuring 4 cm × 1 cm2 for the solar cell space experiment. The “Thin Film Solar Cell (TFSC) Payload” was initially designed to be in orbit for just one year.

Image: Swansea University

“The real innovation is to use the radiation hard glass as the substrate to make the solar cell directly on it,” Lamb explained. “Usually, this glass is stuck onto most solar cells intended for space use and protects them from radiation but adds weight to the already complete solar cell. Our way reduces weight by incorporating the radiation hard glass from the outset.”

Throughout the three years of the experiment, the module showed no signs of delamination, and no deterioration in short circuit current or series resistance. The performance of the aluminum-doped zinc oxide TCE performance was purportedly not affected after three years in space. Their measurements showed that the CdTe solar cell was subject to temperature variations between -3.8 C and 51 C.

Popular content

The device exhibited a power conversion efficiency of around 12%. A reduction in fill factor due to decreasing shunt resistance was attributed to diffusion, to the p/n junction, of the gold back contact. The research team is currently working on an alternative and more stable back contact metal.

“But maintenance of the high short-circuit current value indicates good intrinsic robustness of the CdTe device,” the academics said.

The device's temperature coefficient was found to be -0.19%.

“However, this conclusion should be treated with care as it was not possible to delineate the data for cell temperature only, due to the surveys being conducted under a range of solar fluxes, potentially different light soaking durations and where the open-circuit voltage is also observed to reduce over the three-year time frame,” the academics said.

They described the cell in “Thin film cadmium telluride solar cells on ultra‐thin glass in low earth orbit – three years of performance data on the AlSat‐1N CubeSat mission,” which was recently published in Progress in Photovoltaics.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.